Flying on carbon dioxide

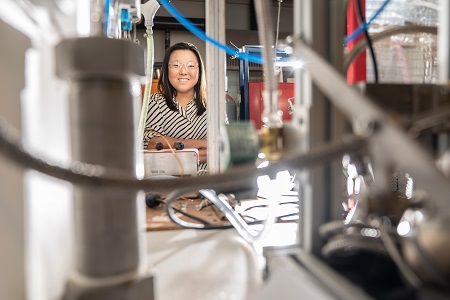

To reduce the greenhouse effect on our planet, behavioural changes are important. But some habits, such as flying, are hard to break. In these cases, technical solutions could make a difference. There are already a number of routes to produce synthetic kerosene. At the University of Groningen, Jingxiu Xie combines her knowledge of catalysis and chemical engineering to produce kerosene from carbon dioxide.

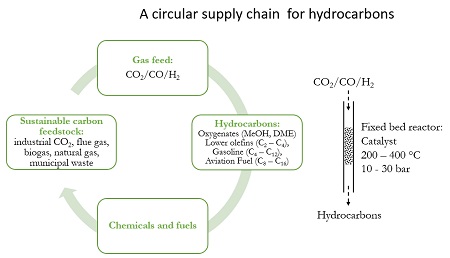

For a chemist, turning carbon dioxide (CO2) into kerosene, an eight- to sixteen-carbon hydrocarbon, is not exactly difficult. ‘The first step is the conversion of carbon dioxide into the more reactive carbon monoxide,’ says Jingxiu Xie, assistant professor of Catalytic Processes for Gas Conversion. ‘We know how this can be done, but it requires a lot of energy.’ Next, the carbon monoxide can be combined with hydrogen (H2) to form hydrocarbons. ‘This is the classic syngas that can be converted into liquid fuel by means of the classic Fischer-Tropsch synthesis reaction.’ The oil company Shell has already used this to demonstrate that it is possible to produce synthetic kerosene.

Energy costs

However, Xie does not want to use a clean source of carbon monoxide (CO) but instead, start with the waste gases from major carbon dioxide emitters, such as Tata Steel or the RWE energy plant in Eemshaven. These waste gases contain many other molecules apart from CO and H2. ‘And the commercial catalysts that are used in the Fischer-Tropsch synthesis reaction do not respond well to this mixture,’ says Xie. ‘We know that it is possible to use a cobalt catalyst to produce aviation fuel from carbon monoxide and hydrogen in the laboratory. But pollutants in the waste gases can result in shorter hydrocarbons. So, we need to combine knowledge of catalysis with knowledge of chemical engineering to get the process working in the way that we want: a fully green production of kerosene.’

On top of this, the energy costs of producing CO from CO2 and obtaining green hydrogen are a problem for green kerosene production. Most hydrogen is now produced from methane, which is not a green source. Xie: ‘And there isn’t enough renewable energy to produce unlimited green hydrogen through the electrolysis of water.’ She is, therefore, working on ways to make the entire process more efficient. This is done by minimizing the purification steps for the waste gas and by tweaking the cobalt catalyst to work better in an industrial process. ‘I have worked in industry for two years and I know how to think like that.’

Small units

Her ideas to produce hydrocarbons using carbon dioxide from waste gases may also change the way in which the chemical industry works. ‘Chemical factories are usually very large and use the economy of scale to produce cheaply. But when we start to use many different sources of carbon for our processes, this may require building small production units near these sources. This will increase costs. So, that is another reason why we have to simplify the production process: to reduce costs.’ The chemical industry would need unsaturated hydrocarbons, so-called olefins, which require a different synthetic pathway than kerosene.

Xie is quietly confident that her approach will work in the near future. And the funding for this type of work is increasing. Her research is a typical example of the work that might benefit from FutureCarbonNL (a collaboration of Dutch universities, knowledge institutes, chemical and other industries, SMEs, and start-ups), which has submitted a multi-million euro proposal to the Dutch National Growth Fund; money that is to be used for investment in carbon capture research. Xie: ‘FutureCarbonNL would certainly be an interesting source of funding for our group.’ This might help her laboratory to develop a process to produce green kerosene for aviation and olefins, while changing the chemical industry at the same time.

See also:

Soil bacteria produce proteins and pharmaceuticals from carbon dioxide

Website FutureCarbonNL

More news

-

13 January 2026

New framework verifies AI-generated chatbot answers