Making green hydrogen cheaper

A sustainable way to produce hydrogen has been around for a century: electrolysis, which produces hydrogen from water. However, it is still much cheaper to make hydrogen from natural gas. That’s why researchers from the University of Groningen are working on more efficient, affordable, and scalable production of green hydrogen.

FSE Science Newsroom | Text Charlotte Vlek | Images Leoni von Ristok

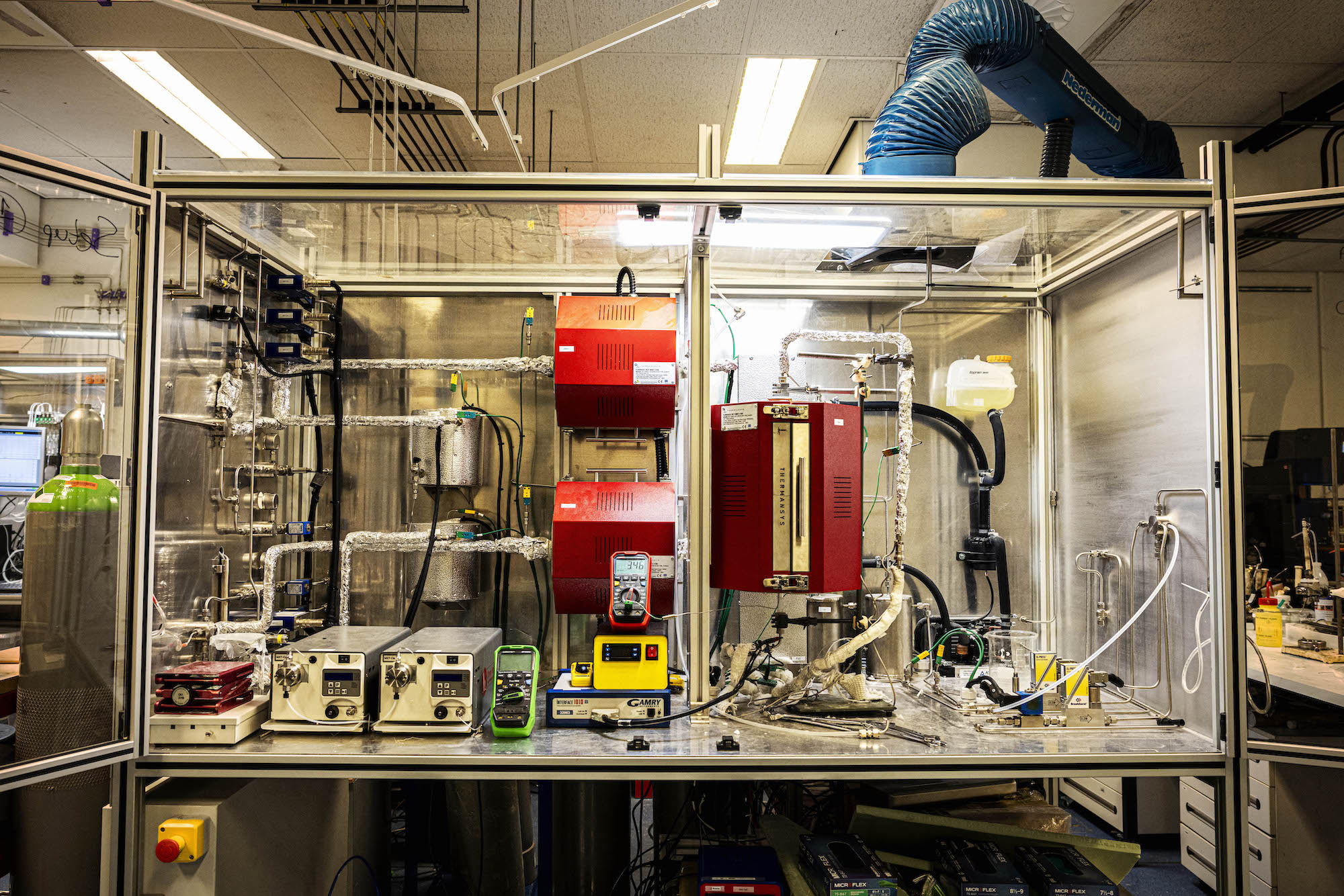

In a lab in the basement of the old Physics and Chemistry building at the University of Groningen, an impressive apparatus is producing hydrogen at high temperatures. But the hydrogen itself is not the goal here. Vassilis Kyriakou, a chemical engineer, is comparing the hydrogen output with the energy input.

This is of an entirely different order than the electrolysis we learnt about in secondary school: let an electric current flow through a container with water and the water will split into hydrogen and oxygen. In Kyriakou’s setup, water is heated and led through a ‘sandwich’ of solid materials in the form of water vapour, at a temperature of over 400 °C. While passing through the sandwich, water is split into hydrogen and oxygen.

The ‘bread’ of the sandwich are electrodes that allow gases (such as water vapour, oxygen, and hydrogen) to pass through, whereas the material in the middle has a special composition that ‘pulls’ the oxygen through to the other side. The result is that hydrogen ends up on one side of the sandwich and oxygen on the other.

Electrolysis: a brief reminder

The simplest setup for electrolysis consists of a container with water and two electrodes that sit in the water. A voltage between these electrodes makes hydrogen and oxygen separate. Since pure water does conducts poorly, some ions need to be added to the water, usually in the form of an acid or a base.

It’s important that the hydrogen and oxygen produced do not come into contact with each other or they will spontaneously react to re-form water. That’s why they need to be separated, usually by placing a membrane in the container.

Water in the form of steam is much easier to split

The perfect sandwich

‘Water in the form of steam is much easier to split,’ Kyriakou explains. ‘Even if you take into account that some energy is needed to heat everything, it can still be more efficient, especially when coupled with industrial processes that operate in a similar temperature range.’ Moreover, this reaction can be reversed, which means that this form of electrolysis can deal with variable wind and solar power supplies: when the power supplies are low, some of the already produced hydrogen can be used to generate electricity to keep the reaction going.

In his lab, Kyriakou’s apparatus allows him to test existing and new materials to make the perfect ‘sandwich’. ‘We’re engineering tailored materials for the electrodes and we’re building electrolysers to test their efficiency. The main challenge is finding the right materials that can endure the extreme conditions, such as the high temperatures required for this type of electrolysis.’

Small things

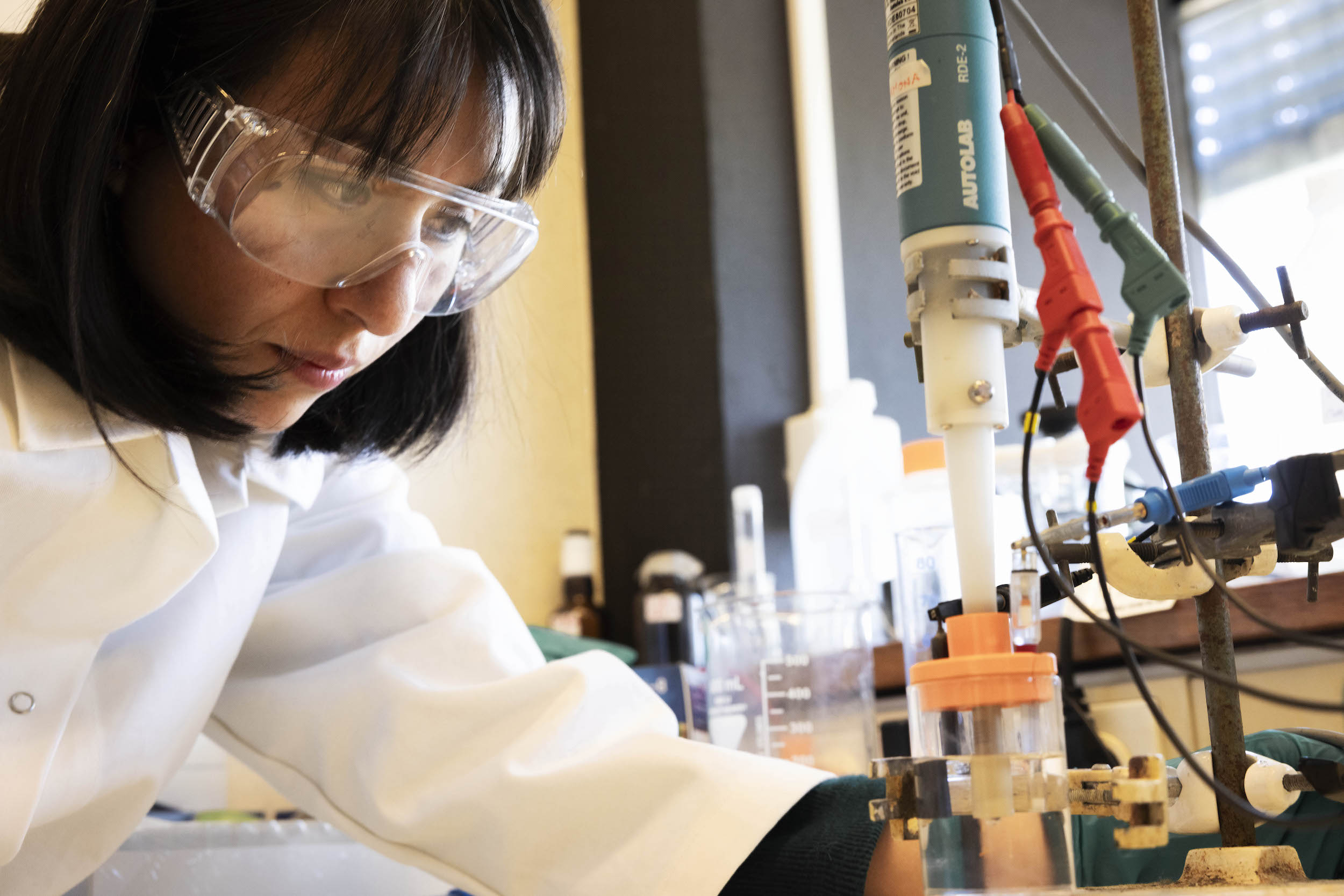

The contrast with the work of electrochemist Dulce M. Morales, could hardly be greater: she works with two connected small beakers, where a membrane can be placed at the connection point. These beakers hold a solution to which appropriate components are added that could make electrolysis happen at low temperatures, which is cheaper and more efficient.

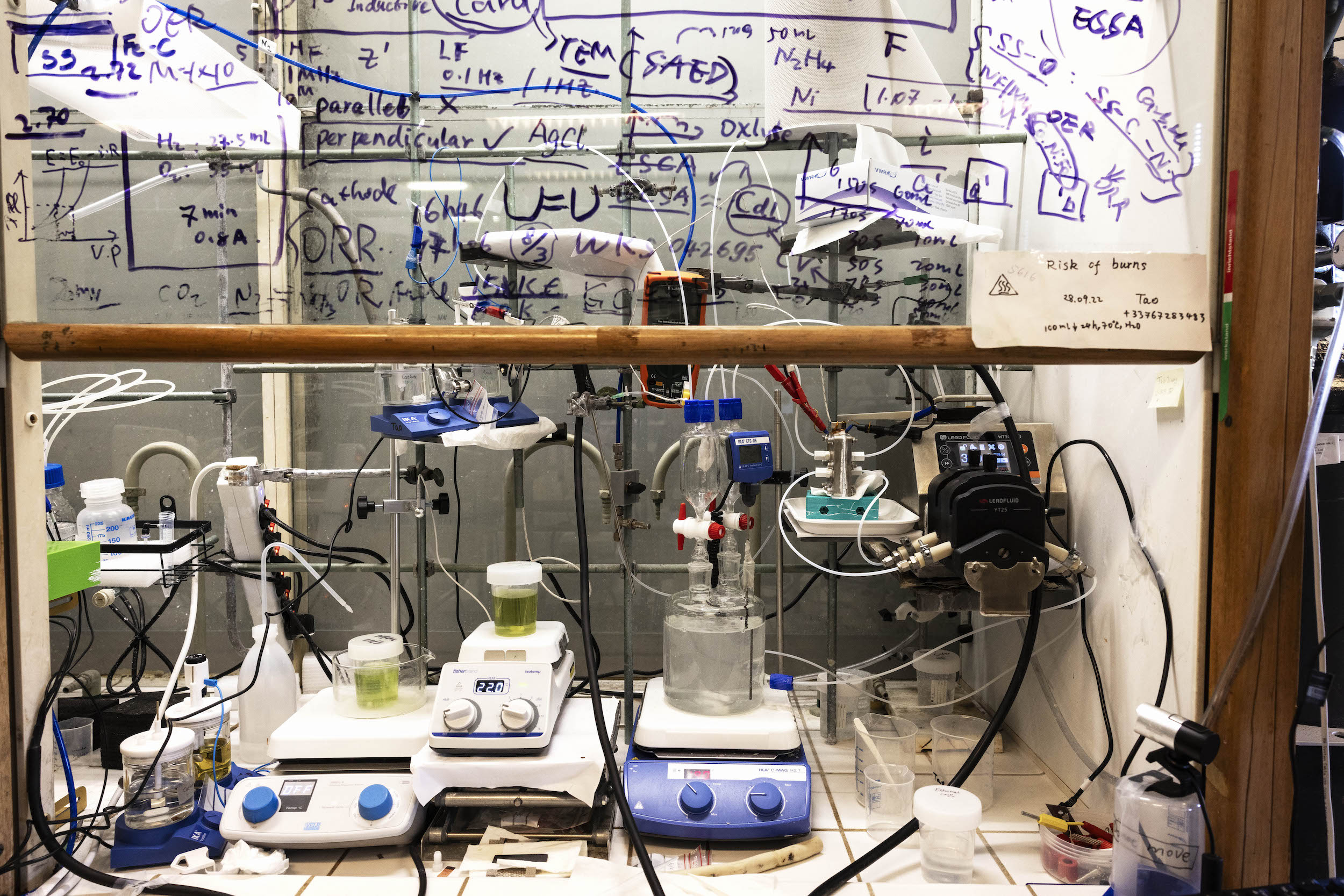

Paolo Pescarmona, professor of Catalysis and Sustainability, is also working on more efficient electrolysis at low temperatures. ‘We’re doing this in the lab, but we are also thinking about scaling up.’ To accomplish the latter, Pescarmona works together with the HydroHub—a facility that was set up in collaboration with the Hanze University of Applied Sciences Groningen and several industrial partners—where various techniques for electrolysis can be tested at a larger scale.

Acid makes for expensive electrolysis

Working in an alkaline environment instead means that cheaper materials can be used

The most efficient form of electrolysis that is commercially available uses water with added strong acids. However, the materials used in this setup are very expensive. Working in an alkaline environment instead means that cheaper materials can be used, although the efficiency is lower. That’s why Morales and Pescarmona are working on increasing the efficiency of electrolysis in an alkaline environment.

One approach they use is searching for alternative catalysts that lower the energy needed for the desired reaction, which will increase the yield. Such catalysts can be added as a coating on the electrodes. ‘We’re looking for materials that can increase efficiency, but that also conduct electricity well and that remain stable and affordable,’ Pescarmona explains.

Morales approaches the same questions more holistically, by looking at the whole system of fluid, electrodes, and the interface where the two meet. By not only looking at the production of hydrogen, but also at potential by-products or other products, the efficiency might also increase.

You’ll always have to add some energy to split water into hydrogen and oxygen. ‘With the right catalyst, you’ll decrease the energy needed to get this process to happen,’ Pescarmona explains. ‘I think my team has found a very suitable strategy to do this and we’ve recently applied for a patent. This could really be a game-changer.’

Which horse will it be?

Pescarmona, Morales, and Kyriakou all work on developing more efficient forms of electrolysis. They each use different approaches, because right now it’s hard to say which approach will be the best. Pescarmona explains: ‘We’re not yet at the point that we can say: this will be the winning horse. And perhaps the result will be multiple viable technologies.’

Making chemical industry greener

Instead of exclusively producing hydrogen, the researchers are also looking at producing alternative end products during electrolysis. For instance, Kyriakou aims to combine hydrogen with abundantly available compounds such as water, carbon dioxide, nitrogen, and biomass. Kyriakou: ‘By combining hydrogen with carbon-based compounds, you can make fuels, or plastics.’ And combined with nitrogen, it becomes ammonia, which is needed for fertilizers or even chemical energy storage.

Kyriakou hopes that his research will make industrial applications greener: chemicals that are already being used in industrial processes can be produced in a more sustainable way. As such, he is working with the Netherlands Aerospace Centre (NLR) and involved with a large European project on the production of green ethylene, a raw material needed for plastics that is usually derived from fossil oils.

Morales also investigates other end products and by-products in her search for more efficient electrolysis: ‘A nice by-product could be an organic acid, for instance,’ Morales explains, ‘such as lactic acid, which is useful for the food industry.’ But really, the possibilities are endless. ‘That’s what makes it fun. The main challenge is selectivity: whether we obtain one product or a mixture of many, which would make it much less usable.’

The Hydrogen Valley Campus Europe is located in the Northern Netherlands. It is the place where green energy comes ashore (from wind turbines on the North Sea), where years of working with natural gas has led to a wealth of experience, and where universities and vocational institutions will work on new research and the education of the next generation of engineers for the hydrogen economy of the future. This is episode 1 of a series on hydrogen research at the Faculty of Science and Engineering at the University of Groningen.

Read more:

Hydrogen is an indirect greenhouse gas: by reacting with other compounds in the atmosphere, it may contribute to global warming in several ways.

Because hydrogen is a much smaller molecule than natural gas, it can easily leak. Even worse, despite its small size, hydrogen can affect larger materials and make them as brittle as glass.

Professor of Energy Conversion Aravind Purushothaman Vellayani is working on systems that use hydrogen to produce electricity – for large factories, for instance. But even your car or your toilet could be capable of producing electricity from hydrogen.

A sustainable way to produce hydrogen has been around for a century, but it is still much cheaper to make hydrogen from natural gas. Researchers from the UG are working on more efficient, affordable, and scalable production of green hydrogen.

Green hydrogen holds many promises. But grey hydrogen from natural gas is still much cheaper, storage of hydrogen is not trivial and as an indirect greenhouse gas is not as clean as it might look.